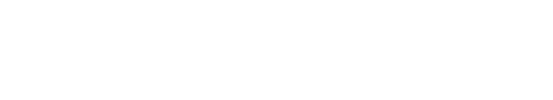

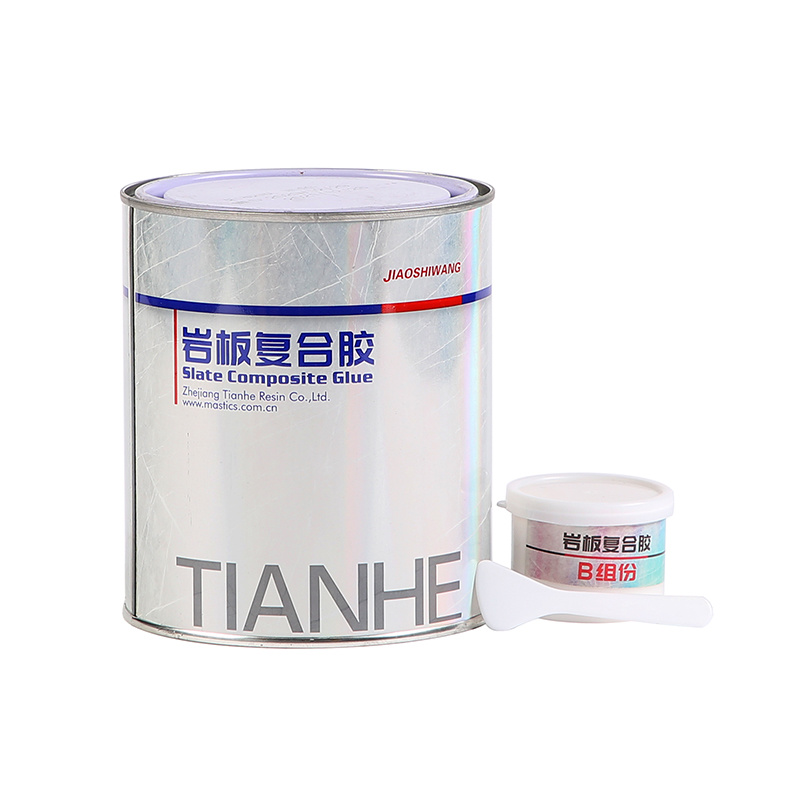

Exclusive Slate Glue

Classification:

Keywords: Slate Glue | Marble Glue | Dry Hanging Glue

Product Description

Product Description

SA-J110 exclusive slate glue is a non-flowing two-component product in cartridge set. It has good weather resistance, high bonding strength and no yellowing by adding new modified materials. Suitable for sintered stone 45° and 90° bonding, also suitable for wood, ceramic plate, granite, quartz stone, artificial marble and other materials composite and bonding. It has fish belly white, light gray, gray, black and other colors.

Features:

● High bonding strength;

● Yellowing resistance;

● Good hot and cold water resistance;

● Good water proof, oil proof;

● Can be used at low temperature (-10℃);

● Fast curing (20-25 minutes).

Product Use

The product is mainly used in the slate processing industry for bonding all kinds of slate board, can also be used for bonding granite, quartz stone, artificial marble and other composite material board, Because of its creamy consistency, fast curing characteristics, widely used in rock plate composite stainless steel, wood, iron and other materials, and has good bonding strength.

Physical Performance

Performance index (23 ℃) | Component A | Component B | |

Before curing | Appearance | thixotropic liquid | Transparent fluid |

Viscosity (mPa · s) | thixotropy | 3000±1000 | |

Specific Gravity | 1.52±0.15 | 1.16±0.03 | |

Fuck. | Component A: Component B (weight ratio) | 100:40 | |

Component A: Component B (volume ratio) | 100:50 | ||

State after mixing | thixotropic liquid | ||

Operable time after mixing | 3-4 minutes | ||

initial curing time | 45-60 minutes | ||

After curing | shear strength | ≥ 10Mpa | |

Hardness | 80±10(shoreD) | ||

Product advantages

1, yellowing resistance to sunlight can be maintained for 10 years without discoloration.

2, environmental protection products themselves no smell, harmless to the body, curing 0 VOC release, in line with national environmental protection requirements. Products have food-grade certification, in line with FDA 21 and EU 1935 standards, can be used for food contact purposes, to avoid customer worries.

3. After easy processing and curing, the appearance and interior are smooth and free of pores, avoiding secondary glue polishing.

4, easy to operate simple operation, the use of hose mixing, reduce mixing time, improve work efficiency. At the same time, the gel speed is adjustable, which can be selected according to customer needs;

5, easy construction has good thixotropy, in line with the plane, elevation construction requirements. Compared with ordinary epoxy, it can be constructed at low temperature (5 ℃).

6, high strength and strong adhesion, waterproof, anti oil.

Instructions for use

1, the adhesive surface should be kept clean, no oil, moisture, etc., recommend the use of 50 mesh dry grinding plate grinding bonding surface, can obtain better strength, better durability of the bonding parts, grinding should be carried out after the second cleaning treatment.

2. Put the plastic bottle into the 2:1 mixing gun, remove the head, install the mixing tube, and push the rod to glue.

3, in the specified operating time, after the use of glue, the bonding parts should be fixed immediately after smearing with adhesive, using uniform contact pressure to colloid curing, to ensure the best bonding effect.

4. After the bonding is completed, keep the bonding parts in a static state. Generally, it takes 45-60 minutes at 23 ℃ before the next process can be carried out. The lower the temperature, the longer the curing time.

Precautions

1, two components of the glue must be sealed storage, for the lid is not used up glue should be sealed in a timely manner.

2, the main component of this product is modified epoxy, harmless to the human body, but not in contact with the eyes, such as contact with the eyes should be immediately rinsed with water, or seek medical treatment.

3. The tool should be cleaned immediately after use, and the adhesive that has not been cured can be scraped or cleaned with acetone.

4. Safety measures at the workplace: gloves, masks, eye shields and other items must be available, and the workplace must be ventilated.

Packaging and storage

1, this product packaging specifications: 50ml.

2. This product should be sealed and stored in a dry place at room temperature and away from light. The original packaging is valid for 12 months.

Management System

This product through the ISO9001:2000 "quality management system" and ISO14001:2004 "environmental management system" certification.

Special statement

This product manual is only responsible for this product. Because there are many factors affecting product performance during use, some factors can only be understood and controlled by users, so users must determine whether this product is suitable for a specific or application.

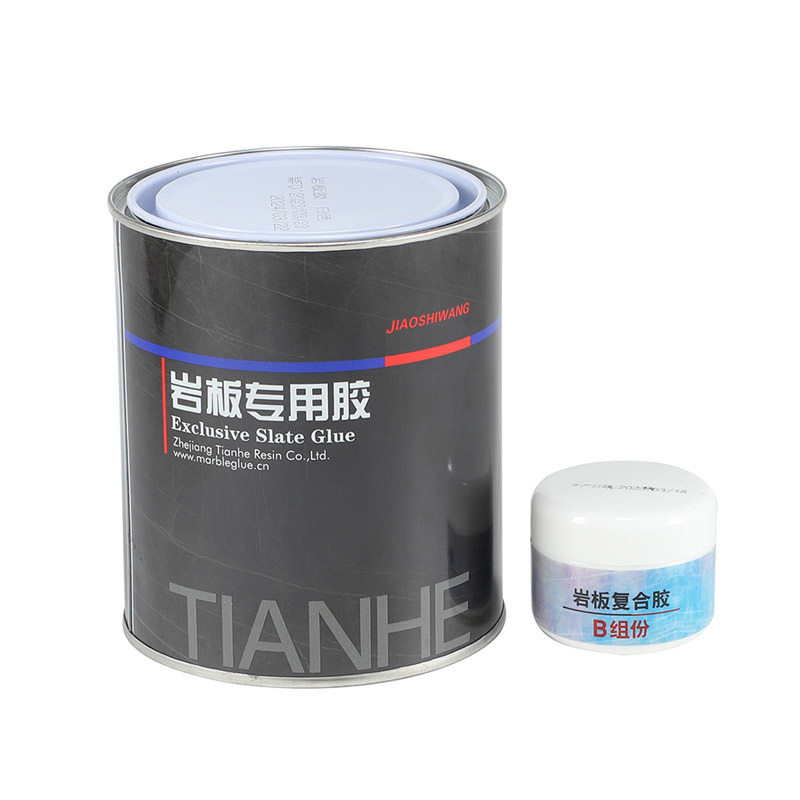

Related Products

Product Consulting