Shiwang Yunshi glue

Classification:

Keywords: Slate Glue | Marble Glue | Dry Hanging Glue

Product Description

Product Introduction

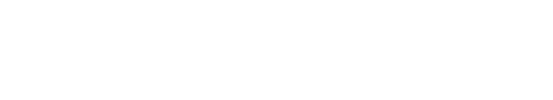

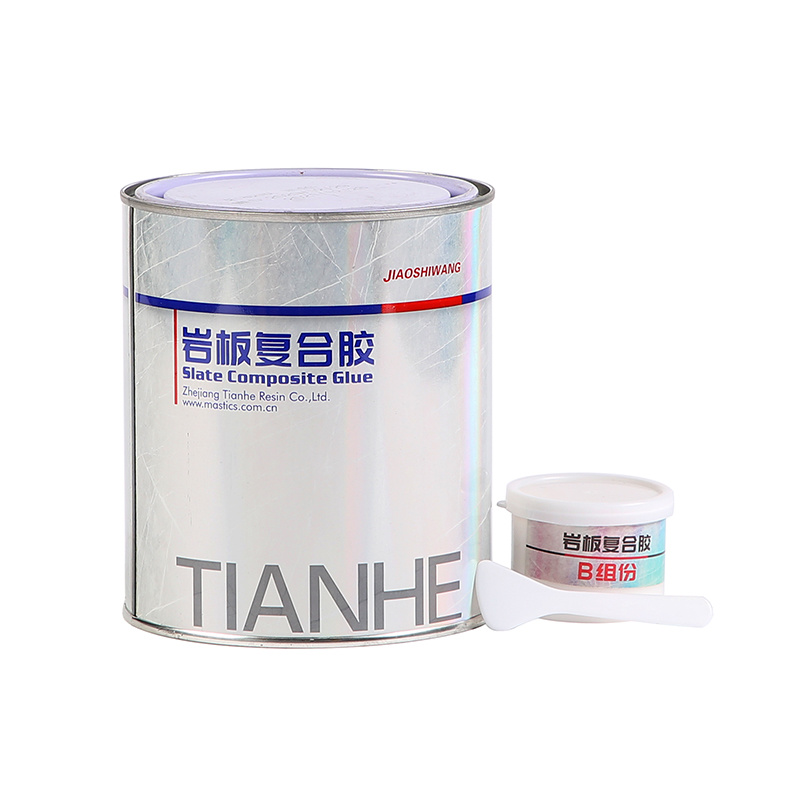

Tianhe Stone Ace marble glue is based on unsaturated polyester resin. This product is developed with high purity, stable and excellent raw materials. After fine and rigorous management control, it has excellent quality. It is suitable for the bonding of various stones in the stone processing industry, especially for the bonding between various types of stones or repairing cracks and broken marks on the stone surface. It has the characteristics of high strength and storage stability, and has the luster of natural stone after polishing. Available in transparent, beige, light rice, beige, white, red, green, black and other colors.

Application areas

The products are mainly used in the stone processing industry to fill and bond natural stone, artificial stone, glass fiber reinforced stone board, etc.

Main composition

Unsaturated resins, peroxides, mineral fillers.

Product characteristics

Dry and thin properly, facade operation without flow, suitable for stone processing industry;

Can be constructed at low temperature (-10 ℃);

With a variety of colors, can be suitable for a variety of plates;

· High hardness after curing, good polishing brightness.

Packing specification

| 0.6 liters/listen | 0.8 liters/listen | 1.0 liters/listen | 3 liters/listen | 4 liters/listen | 5 liters/listen | 20 liters/listen | |

| Box/Barrel | Group of 12 | Group of 12 | Group of 12 | Group of 6 | 4 groups | 4 groups | Group 1 |

Color: transparent, beige, light rice, beige, white, red, green, black.

Product Parameters

■ Technical parameters of strength of marble glue

| Serial Number | Project Name | Test conditions | Test Results |

| 1 | compressive shear strength | Standard state curing for 48h | 17.9 |

| 2 | compressive shear strength | Standard state curing 168h | 17.8 |

| 3 | compressive shear strength | After standard curing for 168h, 100 ℃/168h | 18.6 |

| 4 | Tensile strength | Standard state curing 168h | 19.6 |

■ Physical and chemical characteristics of each composition

Component A:

| Resin Category | unsaturated polyester resin | |||

| Form | Light yellow fluid | transparent paste | colored paste | colored semi-fluid |

| Density (g/㎡) | 1.05-1.15 | 1.35-1.55 | 1.5-1.75 | 1.3-1.4 |

| Viscosity 25 ℃ | 500-900C.P | 1000-3000P | 4500-10000P | 2000-5000C.P |

| Harmful Decomposition | Carbon monoxide and carbon dioxide are released when exposed to fire | |||

| Disposal | Disposal by national and/or regional recognition of formal procedures | |||

Component B:

| Main composition | organic peroxide |

| Form | White paste paste |

| Density | 1.12-1.25 |

| Viscosity 25 ℃ | 1200-2600P |

| Harmful Decomposition | When placed in a fire, it will react violently and release carbon dioxide. |

| Discard processing | Disposal by national and/or regional recognition of formal procedures |

■ Technical indicators:

| Serial Number | Project | Technical indicators | |

| 1 | compressive shear strength stone | Standard conditions | ≥ 10Mpa |

| alkali treatment | ≥ 5Mpa | ||

| hot water treatment | ≥ 5Mpa | ||

| freeze-thaw cycle | ≥ 5Mpa | ||

| 2 | Harmful substance limit | voc content | ≤ 250g/L |

| Benzene | None | ||

| Toluene + Xylene | None | ||

| Formaldehyde | None | ||

Curing time:

Due to seasonal changes, the glue formula will be adjusted. The construction time is 2-5min, the gel time is 3-7min, and the complete curing time is 2-12h.

Method of use:

Add 1-3 parts of curing agent to 100 parts of glue by weight, mix thoroughly (working time after mixing is 3-10 minutes (20 ° C.)), repair, bond and coat on the board.

Note:

Tools should be cleaned immediately after use, and the adhesive that has not been cured can be scraped or cleaned with acetone;

· Safety measures at the workplace: gloves, masks, eye shields and other items must be in place, and the workplace must be ventilated;

When the construction of the eyes or skin is tarnished, should immediately rinse with water, if you feel uncomfortable, should immediately seek medical attention.

Storage and transportation:

· It is valid for 12 months under dark and cool conditions.

· Non-dangerous goods can be transported by car, train, ship, etc.

Product standard:

JCT989-2016

Management system:

This product through the ISO9001:2000 "quality management system" and ISO14001:2004 "environmental management system" certification.

Special statement:

This product manual is only responsible for this product. Because there are many factors that affect the performance of the product during use, some factors can only be understood and controlled by users, so users must determine whether this product is suitable for a specific application.

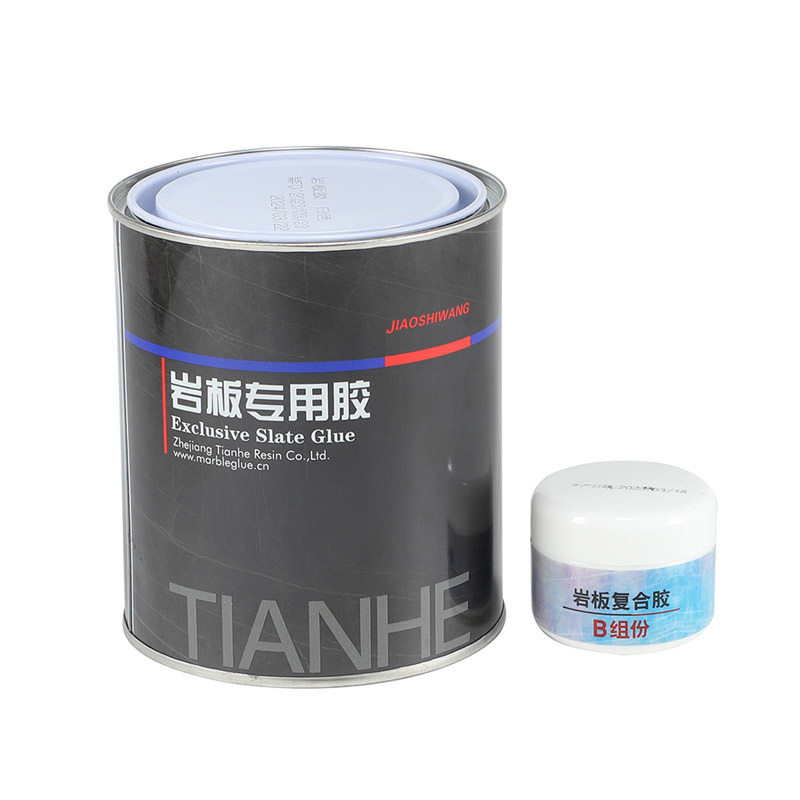

Related Products

Product Consulting